The Only Guide for Premier Aluminum Llc

The Only Guide for Premier Aluminum Llc

Blog Article

The smart Trick of Premier Aluminum Llc That Nobody is Discussing

Table of ContentsWhat Does Premier Aluminum Llc Do?5 Easy Facts About Premier Aluminum Llc ShownLittle Known Facts About Premier Aluminum Llc.Some Ideas on Premier Aluminum Llc You Should Know

(https://premieraluminum.start.page)Utilizing reduced expense and unqualified suppliers can trigger top quality issues, and squandered time and cash in the long run. To help you with the procedure, below are some points to consider when selecting the ideal steel casting provider.

For instance, a firm that just uses the investment spreading procedure will certainly attempt to sell you on why that process is best for your application. Yet suppose utilizing the sand casting procedure is best for you and your requirements? Instead, try to find a vendor that uses a series of casting procedures so the very best alternative for YOU is chosen

If working with a single source for all of your spreading requires is vital to you, the distributor requires to be diverse in its capabilities. When combined with other incorporated abilities, this can help streamline and compress the supply base. When picking the best spreading provider, cautious consideration needs to be offered to top quality, service, and rate.

Some Known Incorrect Statements About Premier Aluminum Llc

Customers progressively select spreading providers that have machining abilities. If the casting provider uncovers an issue during machining, the issue is dealt with much faster with no dispute over whose mistake it is.

Issue or no, incorporated machining simplifies the supply chain and minimizes dealing with time and delivery price prior to the product makes it to the customer. What do you need from your spreading supplier? Are you seeking somebody to simply deliver a metal part to your doorstep or do you require much the original source more? If you do not have internal metallurgy proficiency, confirm that the supplier can give guidance in selecting the proper alloy based on your particular application.

Some foundries are limited or specialized. Make sure the provider can fulfill all your product or alloy needs to eliminate the requirement for multiple suppliers.

Some Of Premier Aluminum Llc

Study the supplier's internet site. Talk to a sales rep or organization associate.

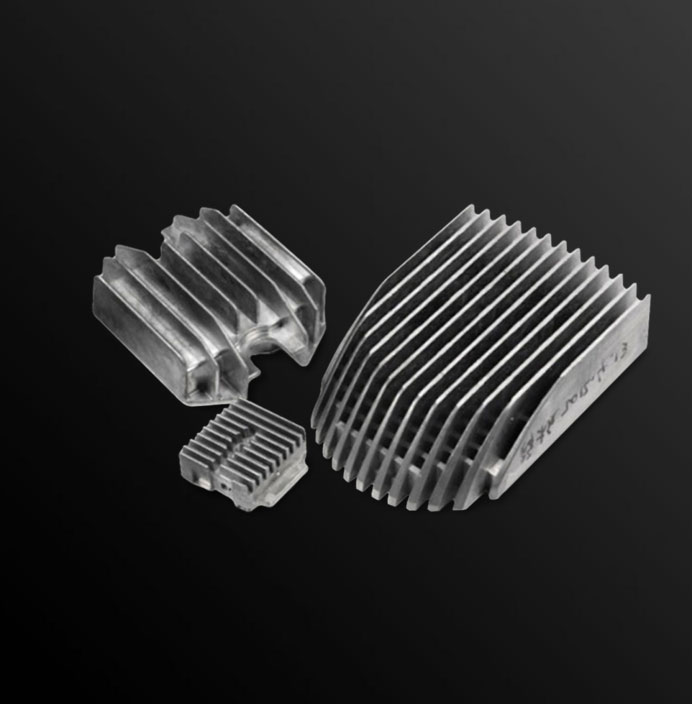

Light weight aluminum is likewise light-weight and has excellent rust resistance, making it perfect for applications where weight and sturdiness are essential aspects. Furthermore, light weight aluminum casting is an economical technique of manufacturing, as it requires much less energy and sources than various other techniques. Iron casting, on the various other hand, involves putting molten iron right into a mold and mildew to develop a desired form.

5 Simple Techniques For Premier Aluminum Llc

Iron spreading is likewise able to stand up to heats, making it appropriate for usage in applications such as engine components and industrial machinery. Iron casting can be extra expensive than light weight aluminum casting due to the greater expense of raw products and the energy needed to thaw the iron. When determining between aluminum casting and iron spreading, it is very important to consider the specific needs of the application.

In final thought, both aluminum casting and iron casting have their own distinct benefits and negative aspects. There are 3 sub-processes that drop under the category of die casting: gravity die spreading (or permanent mold and mildew casting), low-pressure die spreading and high-pressure die casting. To obtain to the ended up product, there are 3 primary alloys used as die casting product to select from: zinc, aluminum and magnesium. Report this page